East Coast Cluster

The six technical documents reviewed and summarized here relate to Net Zero Teesside and the Northern Endurance Partnership, key parts of what is known as the East Coast Cluster. The Cluster aims to go into operation from 2027, storing CO2 from a range of industries in a series of saline aquifers in the southern North Sea, offshore UK. Phase 1 injection via the Endurance store is estimated at 4 MTPA, potentially ramping up to higher volumes later in the life of the facility.

- Getting started

- Technical experts

- East Coast Cluster

About the hub

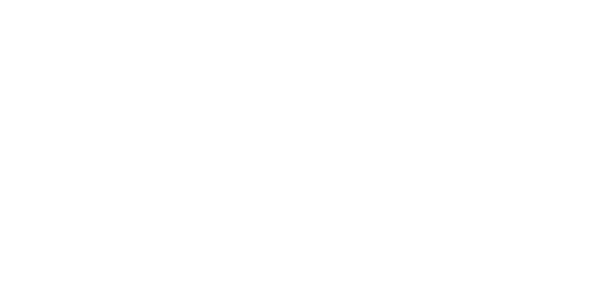

The East Coast Cluster is one of the initial two hubs selected by the UK government for development, in order to meet the UK-wide target of 20-30 MTPA by 2030. It consists of two adjacent clusters, Net Zero Teesside and Zero Carbon Humber, which represented the Teesside and Humber industrial areas during the UK government’s CCUS Cluster Sequencing process. The two clusters share the Endurance storage reservoir which is operated by the Northern Endurance Partnership.

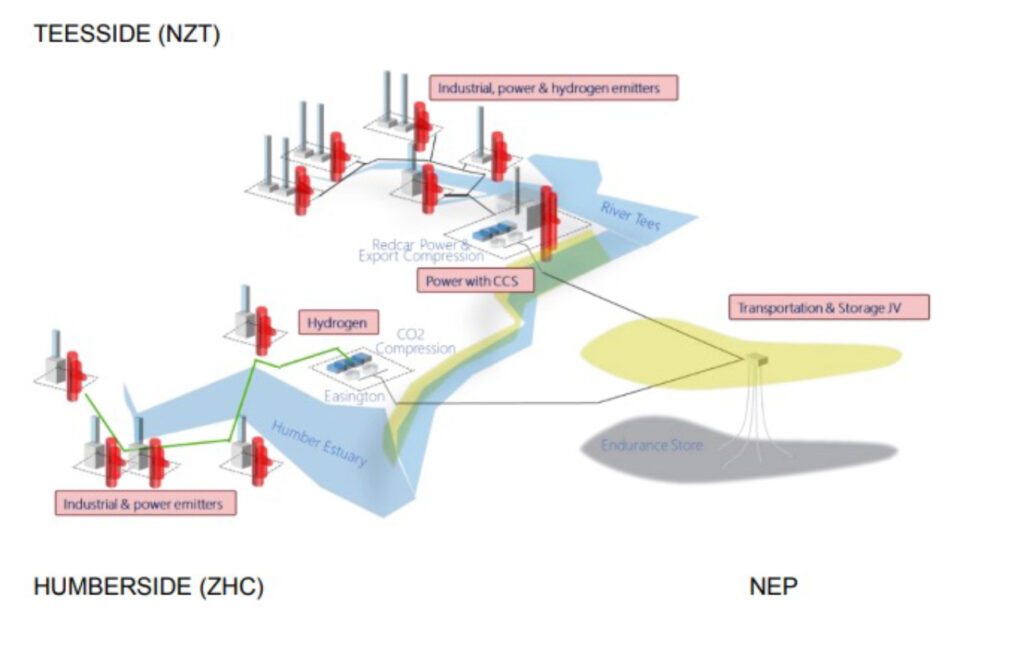

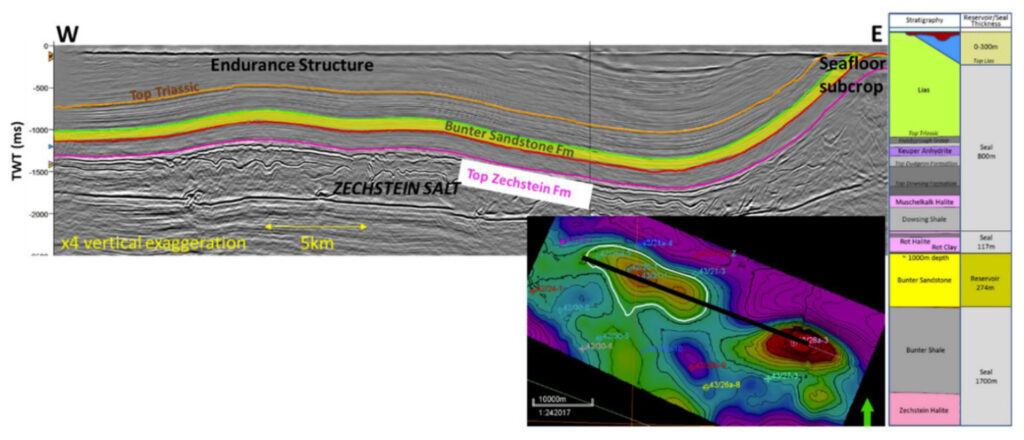

The Endurance structure

The Endurance structure is an anticline approximately 145 km offshore and approximately 1000m below the sea floor. The structure could be used for CO2 disposal into a saline aquifer. The target for CO2 disposal in the anticline is the sandstone of the Triassic Bunter Formation. The Bunter sandstone can be a prolific oil and gas reservoir but, in this structure, there are no hydrocarbons present and any porosity is filled with saline water. The CO2 would be pumped into the Bunter sandstone saline aquifer displacing some of the saline water. Carbon dioxide is less dense than water and would rise to the top of the anticline and be trapped in the subsurface

The Endurance field is a large well-defined anticline, approximately 20 km long and 10 km wide. The anticline is evident even on older seismic data and the crest was drilled in 1970 by Mobil well 43/21-1. This well discovered the anticline but the Bunter sandstone reservoir only contained saline water with no hydrocarbons. In 1990 BP drilled a second well, close to the crest of the structure, 42/25-1 to assess deeper targets in the anticline. The well was unsuccessful in finding hydrocarbons, but it did confirm the wet Bunter sandstone. In 2013, National Grid Carbon drilled a third well down flank on the structure as part of a previous evaluation of the structure for CO2 disposal. This well was part of the White Rose CO2 storage project which was cancelled in 2016. However, some of the data and analysis for the White Rose project have been used in the Endurance project.

Well 42/25d-3 is important as it recovered 190m of core in the Bunter Sandstone. Because the Endurance structure is 1000m below the sea floor much of the data used to build up a picture of the Endurance structure is indirect or inferred. Core data is important because it allows direct examination and measurement of the physical properties of the actual reservoir rock. There are numerous other wells drilled around the structure which can be used to help characterize the Bunter sandstone through the incorporation of well log information. As the Bunter Sandstone is an important economic formation in a large area of western Europe there are many studies, reports and analyses which can be used to help characterise the formation within the Endurance anticline.

Technical review material

This technical review covers six reports related to the evolution of Net Zero Teesside and the Northern Endurance Partnership. The documents were submitted in 2021 by bp (on behalf of the other partners) for review by the relevant UK government department. They are publicly available here.

All the reports represent a summary of the considerable amount of work done under each of the headings. We selected six of the reports to review in detail the purpose, methodology and conclusions associated with each one. Report 1 was selected as it describes some of the different technologies examined for CO2 capture and tackling CCUS scale up. Reports 6-10 were selected, as a group, as they effectively aim to describe the storage container for CO2 (the Endurance anticline) and what might happen when CO2 is injected into that container. The other reports are important and contain valuable information on the project but were outside the scope of this initial review.

It should be emphasized that there is a considerable amount of detailed technical work summarized in these documents which represents a very thorough analysis of this particular reservoir and location for CO2 disposal. The technical work is a very good example of what can be done with respect to analyzing all the available subsurface information. However, the reports should not be taken as an exact template for how to analyze all saline aquifers for CO2 disposal in every location around the globe. This is a very large project and one of the first hence a considerable amount of work was undertaken to decrease risk and uncertainty. As more projects become operational and learnings are shared, evaluation methodologies will evolve. The data requirements and technical work required for future projects will have similarities to the workflow presented for Endurance but will be tailored to each specific project.